From Sprockets to Idlers: The Total Service for Reputable Undercarriage Parts

From Sprockets to Idlers: The Total Service for Reputable Undercarriage Parts

Blog Article

Discover Undercarriage Components for Heavy Equipment

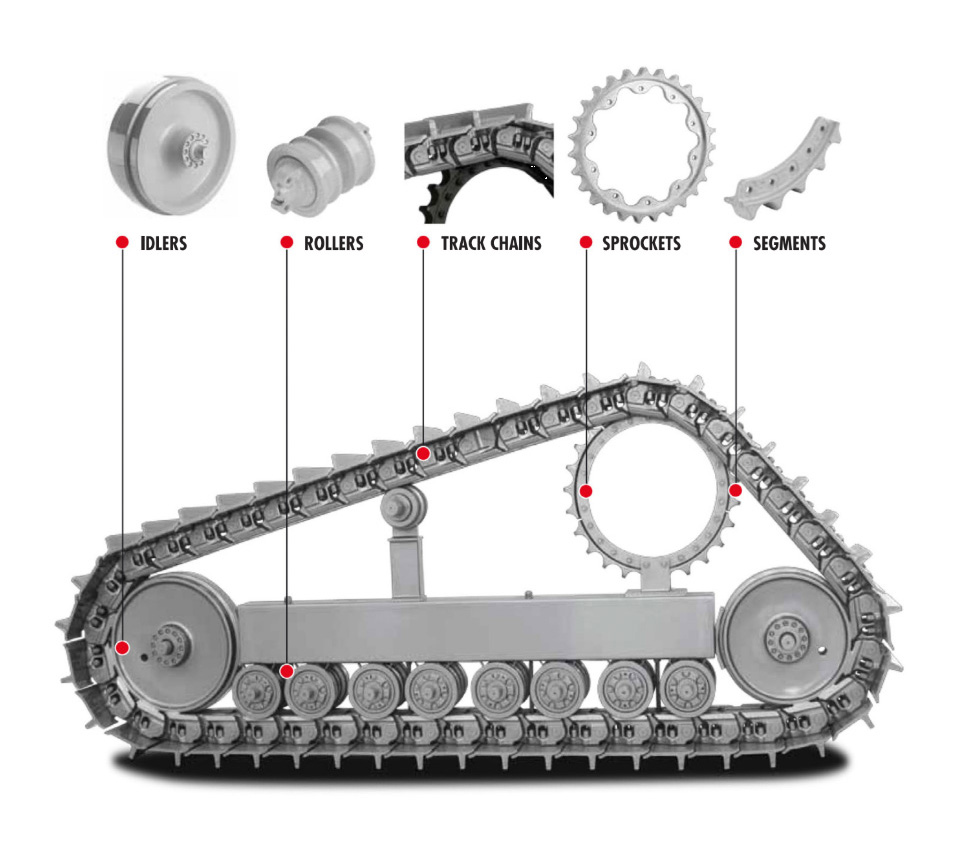

Understanding the details of undercarriage components is necessary for the optimum performance and long life of hefty machinery. From track footwear to sprockets, rollers, and idlers, each element plays an essential role in the performance of the devices. Looking into the specifics of these components introduces a world of precision engineering and durability that keeps heavy equipment operating at its height. Stay tuned as we reveal the relevance of undercarriage components and discover the upkeep techniques that can improve the effectiveness of these essential parts.

Importance of Undercarriage Components

The undercarriage components of heavy machinery play an essential function in guaranteeing the total performance and long life of the devices. These elements, consisting of tracks, rollers, sprockets, idlers, and chains, form the foundation whereupon the machine runs. A properly maintained undercarriage not just supplies security and support to the hefty machinery yet also contributes considerably to its functional efficiency and efficiency.

One of the crucial benefits of purchasing top quality undercarriage parts is the reduction of downtime and maintenance costs. By making use of long lasting components that can hold up against the rigors of durable applications, drivers can minimize the requirement for constant repair services and substitutes, therefore making best use of the device's uptime and overall lifespan.

Furthermore, correctly working undercarriage components ensure ideal weight circulation, maneuverability, and traction, allowing the hefty equipment to operate efficiently also in challenging terrains. This integrity is vital for markets such as construction, farming, and mining, where tools performance directly impacts job timelines and success. In verdict, the significance of undercarriage components can not be overstated in maintaining the efficiency and durability of hefty equipment.

Sorts Of Track Shoes

When thinking about the numerous sorts of track footwear for heavy equipment, it is necessary to examine their design and functionality in regard to certain operational requirements. Track footwear are crucial elements of the undercarriage system, supplying traction, security, and weight distribution for hefty machinery such as excavators, excavators, and crawler cranes.

One of the most typical sorts of track shoes consist of:

** Grouser Shoes **: Featuring raised steel bars (grousers) along the footwear's surface area, these track footwear supply boosted traction in tough terrains like mud, snow, and loose gravel. undercarriage parts.

** Double Grouser Shoes **: Comparable to grouser shoes however with an additional collection of grousers, these track footwear offer also higher traction and security, making them excellent for very rough surfaces.

** Three-way Grouser Shoes **: With 3 sets of grousers, these track shoes give maximum traction and security, making them appropriate for the most requiring conditions.

Selecting the best kind of track shoe is important for optimizing the performance and longevity of hefty machinery while ensuring safety and effectiveness during procedures.

Feature of Rollers and Idlers

Rollers and idlers play essential duties in supporting and guiding the track footwear of heavy equipment during procedure. Rollers are round elements that sustain the weight of the devices and make sure smooth motion along the terrain. They help distribute the device's weight evenly, lowering endure the track shoes and reducing resonances. Idlers, on the various other hand, overview the track chain and aid maintain appropriate tension. By avoiding extreme slack or tightness in the tracks, idlers add to the total security and performance of the equipment (undercarriage parts).

Furthermore, idlers and rollers interact to keep the track shoes in positioning, avoiding them from slipping or thwarting off during procedure. Effectively working idlers and rollers are crucial for making sure the long life of the undercarriage system and optimizing the machine's efficiency. Routine upkeep and examination of these parts are important to determine any type of indicators of wear or damages at an early stage, avoiding pricey fixings and downtime in the long run.

Role of Gears in Equipment

Maintenance Tips for Undercarriage Parts

Effective maintenance of undercarriage parts is crucial for ensuring the durability and ideal performance of hefty machinery. Normal assessment of undercarriage components such as track chains, rollers, idlers, gears, and track shoes is important to avoid expensive repairs and unanticipated breakdowns. One essential maintenance idea is to maintain the undercarriage tidy from particles, mud, and various other pollutants that can speed up wear and deterioration. It is also important to ensure appropriate track stress to avoid early endure components. Greasing the undercarriage parts at recommended periods helps to minimize friction and prolong the life-span of the components. Monitoring for any type of unusual sounds, vibrations, or changes in maker performance can indicate potential problems with the undercarriage that call for immediate attention. By adhering to these upkeep ideas faithfully, heavy equipment Look At This drivers can lessen downtime, decrease running expenses, and make best use of the productivity of their equipment.

Conclusion

In conclusion, the undercarriage parts of heavy equipment play a critical role in ensuring the smooth special info functioning and durability of the equipment. Comprehending the value of track shoes, rollers, idlers, and gears, in addition to carrying out appropriate upkeep practices, can considerably affect the total performance and effectiveness of the equipment (undercarriage parts). Regular inspection and prompt replacement of worn-out components are vital in making best use of the life expectancy and efficiency of hefty machinery

Rollers and idlers play integral duties in supporting and assisting the track shoes of hefty equipment during procedure.In hefty machinery, gears offer a crucial feature in moving power from the engine to the tracks, enabling the equipment to relocate effectively and successfully. These components are attached to the axles or final drives of the equipment and job in combination with the tracks to move the tools forward or in reverse. Regular examination of undercarriage parts such as track chains, rollers, idlers, gears, and track shoes is critical to protect against unforeseen failures and costly repair work. Understanding the significance of this hyperlink track shoes, rollers, sprockets, and idlers, as well as carrying out correct upkeep techniques, can significantly affect the total performance and performance of the machinery.

Report this page